SUPPLIERS

Solo trabajamos con fábricas certificadas que compartan nuestros valores y que busquen reducir el impacto de su actividad. Estas fábricas han de ser entornos seguros donde se cumplan unas condiciones laborales justas y dignas y en donde los trabajadores son retribuidos adecuadamente por su trabajo.

We only work with certified factories that share our values and seek to reduce the impact of their activity. These factories must be safe environments where fair and dignified working conditions are met and where workers are adequately remunerated for their work.

GBTX AND IRIS

GBTX AND IRIS

YEAR FOUNDED: 2016

N° OF EMPLOYEES: 50 PEOPLE

PROCESSES: LAUNDRY, CUTTING, CONFECTION AND PACKAGING

CERTIFICATES: SMETA, GOTS, OCS, GLOBAL RECYCLE STANDARD

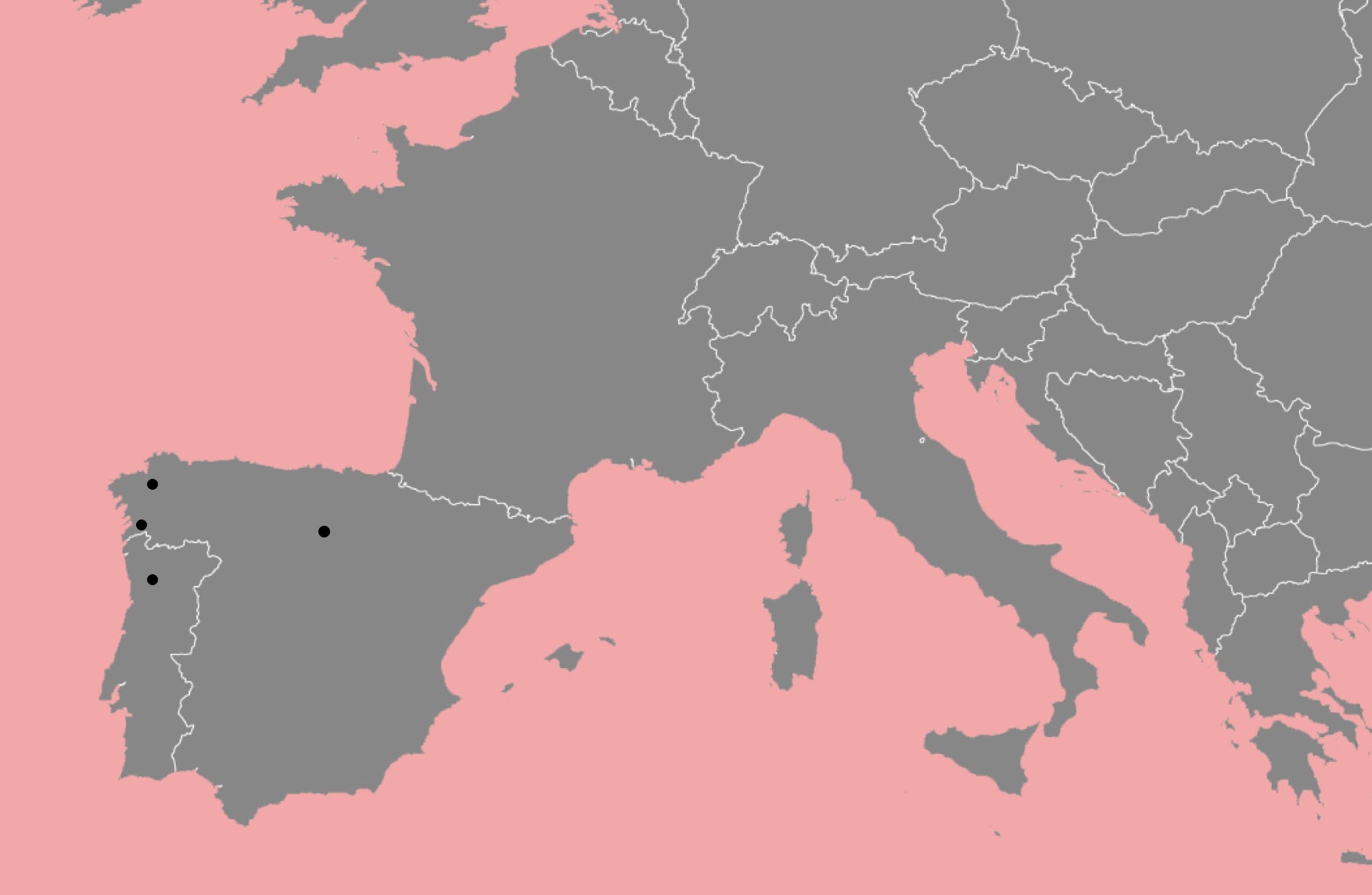

One of the big problems in the textile industry is the number of suppliers needed to make a garment: farm fields, thread manufacturing, fabric, laundry, cutting and sewing... Our solution to this is to concentrate all these suppliers (except the crop field) within a radius of 10km, in this way we can control 100% of the processes involved in the manufacture of our garments. This factory is located just 90 km from our warehouses and 250 km from our offices.

Atrocities against human rights have been committed in this industry, NWHR is not going to contribute to this continuing to happen. Thanks to the SMETA certificate that our factory has, we guarantee that workers carry out their activity in a safe environment and in exchange for fair compensation.

In washing and staining, we use water and a series of dyes that generate waste that must be treated. The laundry has a treatment plant that reuses almost all of the water used in washing and treating fabrics, thus creating a closed circle of consumption and preventing it from being discharged directly into the environment.

In this process, we reduce the water consumed by an organic cotton garment by 72% and save energy and time thanks to the fact that the heat of the discharged water is used to heat the incoming water.

GBTX AND IRIS

KOKOMO TRICOT

LOCATION: ORDES, SPAIN

YEAR OF FOUNDATION: 2016

NUMBER OF EMPLOYEES: 5 PEOPLE

PROCESSES: CUTTING, SEWING AND PACKAGING

CERTIFICATES: GOTS, OCS, FEITO IN GALICIA

This is where we produce all our knitwear, where we do our embroidery, and where we make other garments that you'll soon see at Nowhere.

This charming town in A Coruña, located just 40 km from our offices, was a major textile producer in the 1980s and 1990s.

However, with the arrival of the 2000s, large companies began to relocate their production to Southeast Asia, causing the closure of numerous workshops in Ordes.

For us, it's incredibly important to focus on zero-mile production in Galicia, where we feel we can contribute the most value.

This partnership not only allows us to offer products of exceptional quality, but also helps preserve a tradition and support the local community at a time when the textile industry is facing significant challenges.MMZ SOCKS

MMZ SOCKS

YEAR FOUNDED: 2017

NUMBER OF EMPLOYEES: 7 PEOPLE

PROCESSES: MANUFACTURING AND PACKAGING

This is where we produce our organic cotton socks, a task that Manuel Martinez, founder of the workshop, does perfectly. 3rd generation of professionals dedicated to the manufacture of socks, develop pieces with very high quality threads of Italian origin.

Proximity production is essential for us , not only to reduce emissions from transport, but also to control that the processes and the people involved in them are adequate.